BLOG

Talk About Small Wind Turbine

As a new type of power generation system with low price, reliable operation and no greenhouse gas emissions, the installed capacity of wind power system is being increasingly widely used worldwide with an annual growth rate of more than 30%, which has formed a global industry with an annual output value of more than $5 billion. At present, most of the installed wind power generation systems are MW large-scale fan systems connected with the power grid. The technology of this industry has been gradually perfected. However, the small wind power system used for independent power supply in remote areas still needs to overcome many technical difficulties before it can be widely used. With the increasing investment in "agriculture, rural areas" and sustained and rapid economic development, farmers, animal husbandry and fishermen have urgent requirements for improving the living environment, improving the quality of life and solving the problem of electricity consumption. Small wind power generation system is adopted to provide power for local loads, which can not only reduce one-time huge investment, but also avoid greenhouse gas emissions from thermal power generation system. Improving the environment and the energy mix in rural areas contributes to sustainable development.

Overall Structure And Working Principle Of Small Wind Power Generation System

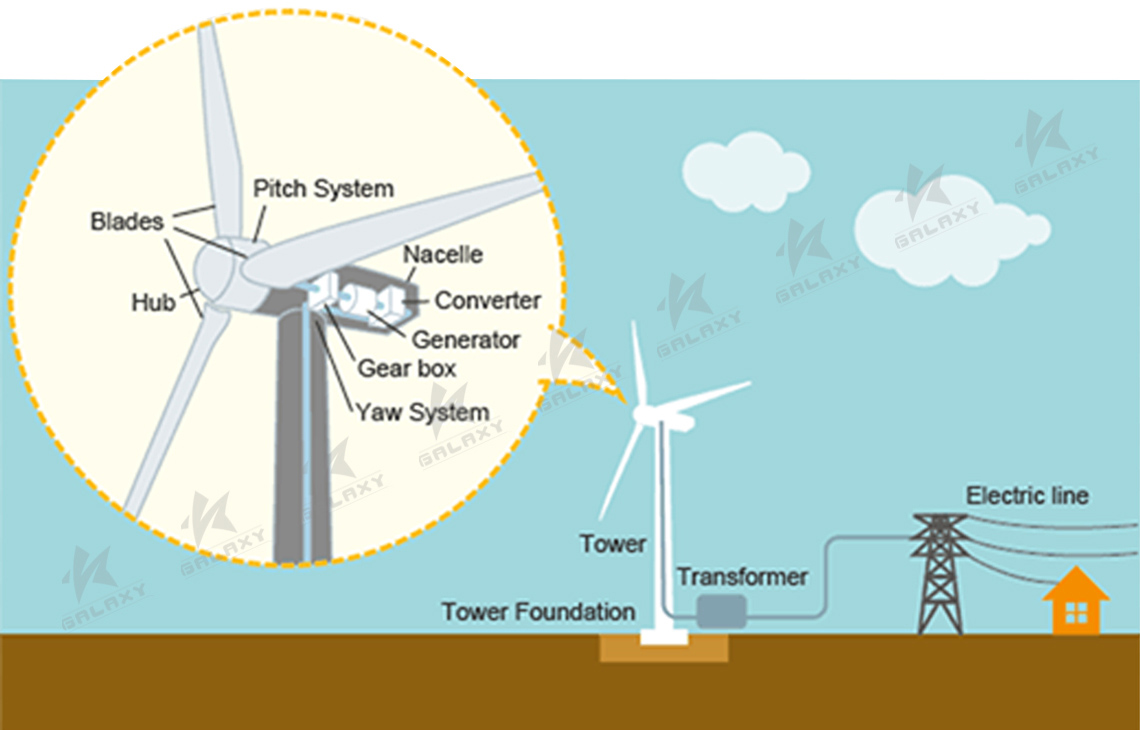

Wind turbines are machines that convert wind energy into electricity. From the perspective of energy conversion, wind turbine is composed of two parts: one is wind turbine, its function is to convert wind energy into mechanical energy; The second is the generator, whose function is to convert mechanical energy into electricity.

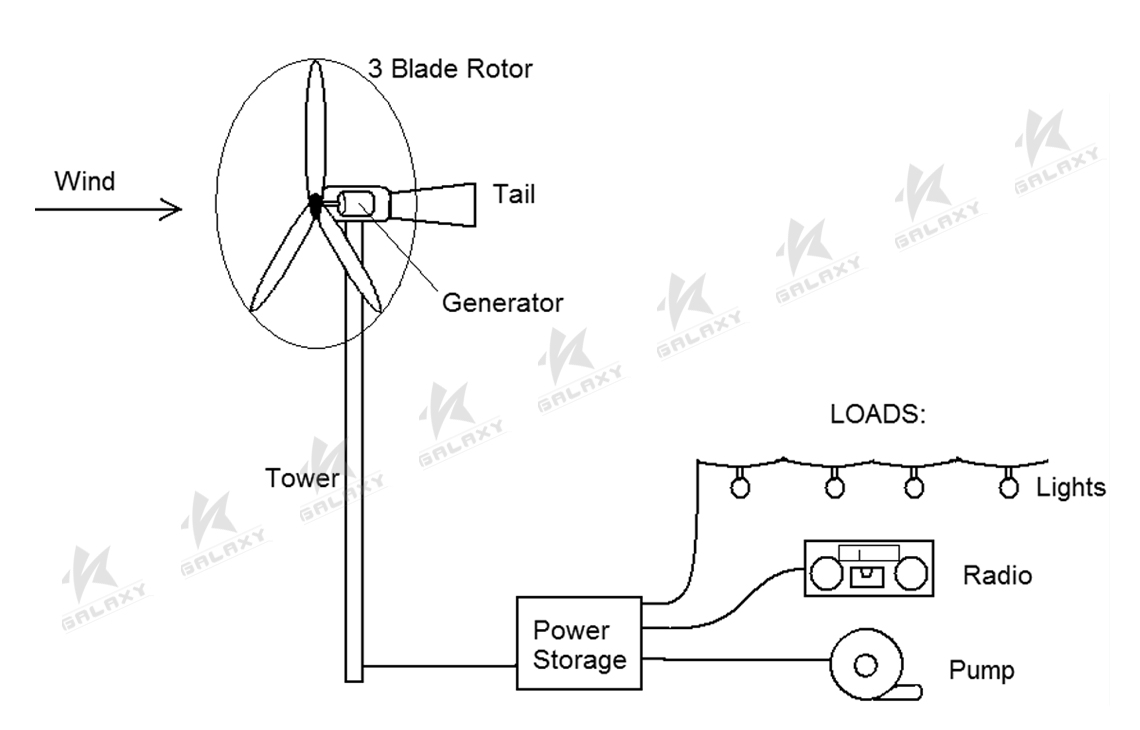

Small wind power generation system is generally composed of wind wheel, generator, tail rudder and electrical control part. The conventional small wind turbine is mainly composed of induction generator or permanent magnet synchronous generator plus AC/DC converter, storage battery and inverter.

When the wind blows, the wind wheel rotates, transforming aerodynamic energy into mechanical energy (rotational speed + torque). The hub of the wind wheel is fixed on the generator shaft, the rotation of the wind wheel drives the rotation of the generator shaft, and drives the permanent magnet three-phase generator to emit three-phase alternating current. The current and voltage from the generator vary as the wind speed changes. The generated electricity is rectified by the controller, from alternating current to direct current with a certain voltage, and charges the battery. Direct current output from the battery, through the inverter into 220V AC, to the user's household appliances.

Wind turbines can be divided into grid-connected type and off-grid type according to different applications. Off-grid wind turbines, also known as independent wind turbines, are used in areas without power grids and generally have low power. Independent operation of wind turbine generally needs to be combined with battery and other control devices to form independent operation of wind turbine power generation system. This independent operation system can be several kW or even tens of kw, which can solve the power supply system of a village, or can be dozens to hundreds of W small wind turbine to solve the power supply of a household.

Power Conversion Device Of Small Wind Turbine

Due to the randomness of wind energy, the frequency and voltage of the electric energy emitted by the generator are unstable, and the battery can only store the direct current energy, unable to supply power to the AC load. Therefore, in order to provide stable and high-quality electric energy for the load and meet the requirements of AC load, it is necessary to add a power conversion device between the generator and the load, which is mainly composed of rectifier, inverter, controller, battery and so on.

Rectifier

The main function of the rectifier is to rectify the three-phase alternating current output by the wind turbine, and then charge the battery after the rectified direct current through the controller. Generally used are three - phase bridge rectifier circuit. Another important function of the rectifier in the wind power branch is that the output power of the wind turbine is small when the external wind speed is too small or basically no wind. Because the diode conduction direction of the three-phase rectifier bridge can only be from the output end of the wind turbine to the battery, it prevents the reverse power supply of the battery to the wind turbine.

Independent operation of small wind power generation system, there is a wind wheel driven alternator, need to be equipped with appropriate rectifier, to charge the battery. According to the capacity of the wind power system, the rectifier is divided into two types: controllable and uncontrollable. The controllable rectifier is mainly used in the system with large power, which can reduce the disadvantages of large volume and loss caused by excessive inductance. Uncontrolled rectifiers are mainly used in low power systems.

Inverter

Inverter is often used in the process of power transformation of a power electronic device, its main role is to store the battery or by the rectifier bridge output of direct current into the load can use the alternating current. At present, the inverter of independent operation of small wind power system is mostly single phase bridge inverter. The inverter used in wind power generation requires high efficiency, especially in light load, because the wind power generation system often runs in light load state. In addition, because the input battery voltage changes with the charging and discharging state, it requires that the inverter can work normally in a larger range of DC voltage changes, but also to ensure the stability of the output voltage.

In the past, the controller and inverter of wind turbine are separate, now most manufacturers use the controller and inverter integration scheme. The controller recites the alternating current from the generator and charges it into the battery bank. The inverter converts the DC output of the battery to 220V AC and supplies it to the electrical appliances.

Inverters are divided into two types according to the input mode:

(1) DC input: inverter input directly connected with the battery;

(2) AC input type: the inverter input terminal is connected with the AC output terminal of the wind turbine generator, that is, the integration of control and inverter products.

Inverter protection functions include:

(1) Overcharge protection: when the wind speed is continuously high, the battery is fully charged, and the battery voltage exceeds 1.25 times the rated voltage, the controller stops charging the battery, and the excess current flows to the unloader.

(2) Over-discharge protection: when the wind speed is low for a long time, the battery is insufficient to charge, and the battery voltage is lower than the rated voltage of 0.85 times, the inverter stops working and no longer supplies power to the outside. When the wind speed increases again and the battery voltage recovers to 1.1 times of the rated voltage, the inverter automatically recovers and supplies power to the outside.

Batteries

Accumulators are widely used as energy storage devices in independent small-scale wind power generation systems. The role of the battery is that when the wind is strong or the load is reduced, part of the electric energy from the wind generator can be stored in the battery, that is, to charge the battery. When the wind is weak, there is no wind or the power load increases, the electric energy stored in the battery supplies power to the load to make up for the shortage of the power generated by the wind turbine, so as to maintain the role of continuous and stable power supply to the load.

Batteries mainly include ordinary batteries, alkaline cadmium nickel batteries and valve-controlled sealed lead-acid batteries. Ordinary lead-acid batteries are limited in use because of their short service life, low efficiency, complex maintenance, acid fog pollution and other problems. At present, they have been gradually eliminated by valve-controlled sealed lead-acid batteries. Valve-controlled sealed lead-acid battery as a whole with a sealed structure, there is no ordinary lead-acid battery gas boom, electrolyte leakage phenomenon, the use of safe and reliable, long life, normal operation without the need to detect the electrolyte and acid and water, also known as maintenance-free battery, has been widely used in post and telecommunications, ship traffic, emergency lighting and many other fields. Alkaline nickel-cadmium battery is characterized by small volume, high discharge rate, simple operation and maintenance, long life, but because of its single low voltage, easy to leak, high cost and easy to cause environmental pollution, so its use is limited, is now mainly used in electric tools and various portable electronic devices.

At present, the valve-controlled sealed lead-acid battery is used in most wind power system or solar photovoltaic system. Battery is a key factor affecting the life of wind power system. The control of charging and discharging of valve-controlled sealed lead-acid battery directly affects the life of the battery. Unreasonable charging and discharging will directly lead to the collapse of the battery. In most wind power systems, the CPU is used to monitor and control the charging and discharging process of the battery, and more use the phased method to optimize the charging process. Because the phased charging process conforms to the characteristics of the valve-controlled sealed lead-acid battery, it can protect the battery well and extend its service life.

Maximum Output Power Adjustment Mode

In wind power generation, the utilization of wind speed is difficult because of the change of wind speed. The change of wind speed makes the output mechanical power of wind turbine change, so that the output power of the generator fluctuates and the power quality decreases. The stability of the output power quality of wind turbine becomes an important problem in wind power generation technology. Therefore, it is of great significance to improve wind power generation technology and improve the efficiency of wind turbines to make the best use of wind energy resources.

According to the different power supply modes of wind power generation, the power output is qualitatively divided into two categories: adjusting the mechanical power, adding a regulating device in the control loop of wind turbine to make the output mechanical power of wind turbine stable; Adjust the electrical power, add feedback to the control part of the generator, and control the output power of the generator using a fast response controller and optimal control strategy.

Adjusting Slurry Distance Stall

The stall adjustment mode refers to the stall characteristics of the blade itself. When the wind speed is higher than the rated wind speed, the Angle of attack of the air flow increases to the stall condition, causing eddy currents on the surface of the blade, reducing the aerodynamic efficiency of the blade and affecting the energy capture. Maximum power control of small wind power system stall adjustment by disturbance method is generally used in wind turbines running at constant speed.

Adjustment of Slurry Distance

In order to improve the efficiency of wind energy conversion and ensure the steady output power of wind turbine, the wind turbine can adapt to the change of wind speed by adjusting the slurry distance to achieve the optimal power output. The wind turbine with variable pitch does not completely depend on the aerodynamic characteristics of the blade, but mainly depends on the change of the blade attack Angle matching with the blade to adjust the wind energy conversion efficiency. In the stationary period, the distance Angle is 90°. In this case, the air flow does not produce torque on the blade, and the whole blade is equivalent to a damping plate. When the starting wind speed is reached, the blade rotates in the direction of 0°, the air flow produces a certain Angle of attack on the blade, and the impeller starts to rotate. When the rated wind speed is below, the blade Angle of attack is near 0°. At this time, the blade Angle is affected by the control accuracy, and the variation range is small, which can be equivalent to the constant slurry moment fan. When the rated wind speed is above, the pulping distance mechanism plays a role to adjust the blade Angle of attack to ensure that the power of the generator is within the allowable range. The start-up wind speed of the wind turbine with variable slurry distance is relatively low, which has little significance for increasing the power generation. The impact on the transmission mechanism is small when the wind turbine is shut down, and the power control is mainly adopted when the wind turbine is working normally.

Active Stall Adjustment

This regulation mode is a combination of the previous two power regulation modes. At low wind speed, the grouting distance can be adjusted to achieve higher aerodynamic efficiency. When the fan reaches the rated power, the fan changes the fan distance in the opposite direction when the fan adjusts the fan distance. This adjustment will cause the change of blade Angle of attack, resulting in deeper stall and smoother power output. This adjustment method integrates the advantages of the first two adjustment methods, similar to the slurry distance adjustment, but does not need a very sensitive adjustment speed, strong wind, the impact of the whole unit is small.

Closing Remarks

As a component of rural energy, the popularization and application of small-scale wind power generation system will play a positive role in improving the electricity structure, especially the production and living energy in remote mountainous areas, and promoting the development of ecological environment construction. Therefore, it has a broad market prospect. Wind energy has randomness and uncertainty. Wind power generation system is a complex system. It is of great significance to simplify the structure, reduce the cost, improve the reliability and optimize the operation of small wind power generation system.